The Facts About 24hr Media Revealed

The Facts About 24hr Media Revealed

Blog Article

Getting The 24hr Media To Work

Table of Contents24hr Media Fundamentals ExplainedExcitement About 24hr Media24hr Media Can Be Fun For Everyone24hr Media for BeginnersRumored Buzz on 24hr Media

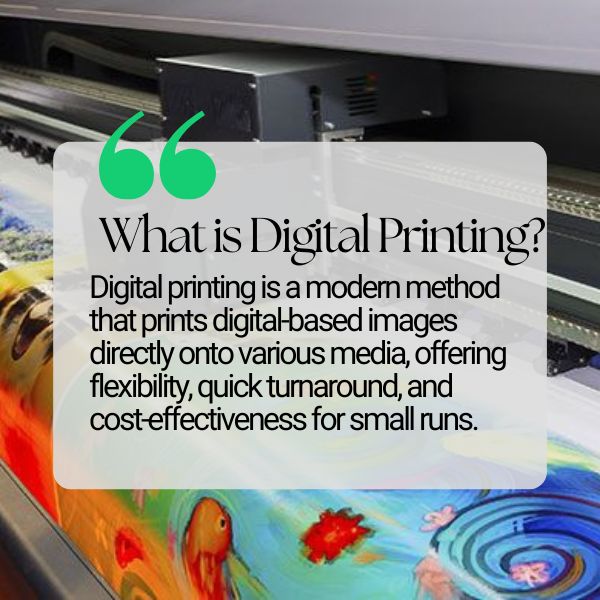

Developments in print technology are transforming the interactions playing area when it pertains to quality, price and sophisticated capabilities. Balanced out printing and electronic printing are the major processes by which print tasks are undertaken both utilizing four-color printing methods. Each choice has its advantages, providing various techniques to fulfill the requirements of diverse production tasks.

Usually, this has actually been one of the most regular method for precisely preserving shade suits, making it optimal for print runs that only need static printing such as pre-printed types, brochures, flyers, calling card, and mass postcard mailings. However, because of the fixed nature of litho printing, it is not suitable for variable print items that will be mailed to specific recipients such as declarations, letters, and customized postcards.

The 5-Second Trick For 24hr Media

The newest developments in print technology are assisting to bring many of balanced out's benefits into the digital printing world genuinely changing the face of modern printing! There are some key differences between Offset Printing and Digital Printing.

Today's electronic print devices is amongst the most cutting-edge on the market. Right here are several of the greatest benefits of using digital printing: control the electronic print area, with full-color printing completed in one process and perfectly printed straight from a print file. Without an extensive set up process, the calibration time of a details task is shortened, adding to quicker print time and general delivery.

The inkjet printing process has actually aided to revolutionize the market as well as the quality and speed of the result. The current inkjet innovation can print on standard countered stocks with boring, silk, and shiny surfaces. Top quality digital print paired with software-managed shade administration practices adds maximum value to print items and makes manufacturing processes extra dependable than balanced out.

The Single Strategy To Use For 24hr Media

(https://sandbox.zenodo.org/records/164208)

Eco-friendly and eco-friendly inks and toners are also available for more sustainable printing. Digital print likewise gets rid of the demand to clean plates or coverings with dangerous chemicals at the end of the printing procedure.

Variable data aids companies reach their exact customers and audience with uniquely-created and individualized web content. As technology boosts, the top quality of digital printing has ended up being second-to-none, with higher detail, color match capabilities and overall precision. Without the demand to clean plates or use excess ink, electronic printing is additionally much less wasteful and normally more eco-friendly.

Traditional printing approaches, such as offset lithography ("balanced out") and flexography ("flexo"), include numerous make-ready steps to move an original image to a substratum. These methods need the production of a collection of plates placed on a cylinder to move ink that creates the preferred picture when integrated on paperboard and other product packaging products. Window Vinyl.

The smart Trick of 24hr Media That Nobody is Discussing

While electronic printing is a viable alternative for many short-run print tasksspecial events, prototyping, or other considerationsits modern capabilities really reveal in fast turn-arounds. Having the ability to customize product packaging via variable information printing has opened up brand-new chances for you to involve with your customers in even more customized means. Digital printing, with fewer moving pieces, is much more agile than balanced out in this regard.

It's a method to mix your product packaging and advertising and marketing strategies. Decreased set-up time conserves money on the front end. And since these are not enormous bulk orders, smaller sized organizations can afford to publish without needing to meet the higher and a lot more costly print thresholds of conventional printing. Digital printing helps safeguard your brand name versus counterfeiting by including overt and covert services on your packaging.

Make certain you team up with a printing and product packaging companion who has the best certifications. While eleventh-hour printing and modification are a big advantage, electronic may not constantly be the finest method for you. As an example, balance out printing has the benefit of cost-effectiveness with big print runs, specifically those with advanced decorative impacts and specialized layers.

Getting The 24hr Media To Work

Lithographic presses use two print platesa favorable and a negativeto transfer top quality shade graphics onto an appropriate substrate. The favorable plate, with its smooth surface, draws in oil-based inks and fends off water. On the other hand, the adverse plate, with its rough texture, takes in water and drives away oil. Rubber rollers are after that utilized to transfer the photo from home plate to the corrugated surface.

Corrugated paper view website can often verify to be a difficult surface area to publish on, yet Litho prints to a different surface and is after that laminated to it, making it very easy to publish premium photos. It can be extremely constant, even for lengthy runs. The much more you publish, the less expensive the expenses end up being for Litho.

What Litho doesn't offer you is precisely what Digital does, modification. Pricey set up Longer turn-around No Variable Data Printing Smaller sized shade gamut, shades can be much less bright Digital printing is the process of printing digital photos directly onto the corrugated substratum utilizing a single-pass, direct-to-corrugate technique.

Report this page